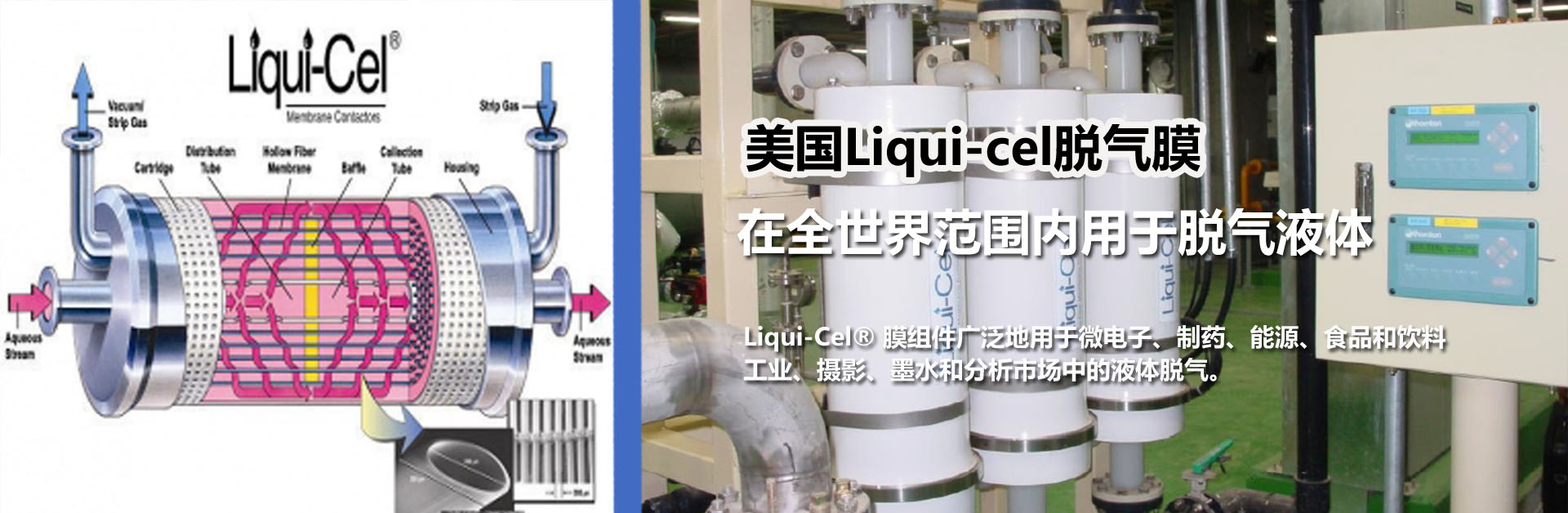

制药工业需要连续不断的纯水源,其导电率小于1.3 µS/cm。 控制和去除水中溶解的CO2将可使水达到这一导电率水平。 历史上,带有NaOH化学药品被用来控制CO2 现在,人们不再使用化学药品,因为它们对环境有负面影响,而且对处理这些化学药品的人存在安全隐患。 此外,EDI 和 CDI 已成为制药工业中离子交换的普遍技术。 如果提前将溶解的CO2从水中去除,这些技术能够更加有效地实施。 水中过多的 CO2 将加重 EDI 的负担,而且与必需的EDI膜堆相比,需要更多。 制药工业同样也需要没有 污染物的高水质。 Liqui-Cel膜组件为制药工业中的气体控制提供了一个理想的解决方案。 Liqui-Cel系统是封闭系统,不在水中引入环境污染物,就像早先的强制通风脱气器所作的一样。 它们也可以替代使用化学溶液的压注。 膜组件也可同时去除O2 和 CO2 ,这对于任何氧气对最终产品有负面影响的过程都有好处。 有时候,氧气会影响保存期限和产品稳定性。 接触器提供了一个简便的气体去除系统,可以每天无故障地运行24小时,一周运行7天。

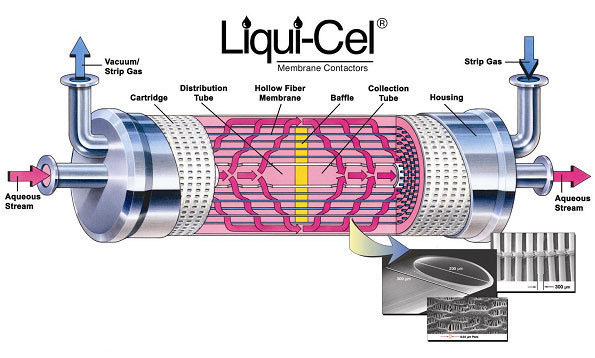

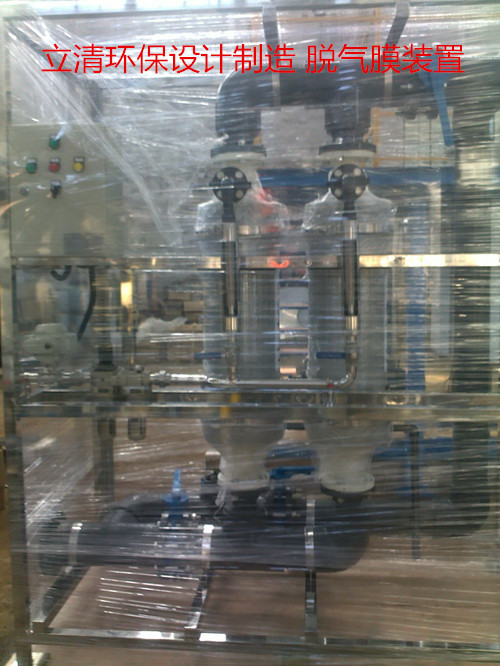

Membrane contactors

reduce chemical use and blowdowns

Schematic of the

Liqui-Cel Membrane

Contactor

Provided by Membrana

Proper treatment of boiler

feedwater is an important

part of operating and main-

taining a boiler system. As steam is

produced, dissolved solids become

concentrated and form deposits

inside the boiler, leading to

poor heat transfer and

reduction of boiler efficiency.

Dissolved gasses, such as

oxygen and carbon dioxide,

react with metals in the boiler

system, resulting in boiler corrosion.

These gasses should be controlled or

removed to protect the boiler.

Several different technologies are

widely used in the industry to remove

these contaminants. Reverse osmosis

membrane and ion exchange systems

can remove dissolved solids. Forced

draft degasifiers, chemical agents and

steam de-aerators have historically

been used to remove dissolved gasses.

Membrane contactors are increas-

ingly being used to remove dissolved

gasses in boiler feedwater. Widely

used in the semiconductor, power,

pharmaceutical and other industries to

control dissolved gasses in water

systems, their use in boiler feedwater

degasification systems has grown

steadily since the development of new

industrial grade devices.

Membrane contactors contain micro-

porous hydrophobic membranes,

which are used to bring gas and

liquids in direct contact without

mixing. Contactors operate by

lowering the pressure of gas in contact

with the liquid to create a driving force

to remove the dissolved gasses from

the water. They are highly efficient and

compact, and can be used inline under

pressure.

Chemical treatment

Chemical treatment is widely used to

control dissolved oxygen in a boiler.

The cost of operating a chemical

treatment program consists of chemical

costs and blow down costs. As the

water is converted to steam, non-

volatile compounds in the boiler feed

water are concentrated inside the

boiler. Periodically the water in the

boiler must be flushed out to remove

these compounds by a process called

blow down. Any chemical that is

added to the water can increase the

frequency of blow down, which affects

operating costs of the boiler.

The cost of blow down can be broken

down into two costs – water and

heat/energy. First, water and steam

that is purged from the boiler during

blow down is drained, so this water

must be replenished by fresh makeup

water. Second, the water blow down

from the boiler is hot and is replaced

with cold water that must be reheated

to produce steam. Energy costs can be

calculated by looking at the energy

needed to heat the water back to the

temperature of the steam produced by

the boiler.

In smaller low-pressure boilers

(<10,000 lbs/hr and < 50 psig),

chemical treatment alone may be used;

a combination of steam deareation and

chemicals is most often used

for larger high-

pressure boilers. For ease of calculation,

a small low-pressure boiler using a

chemical program only will be eval-

uated in this paper. These same calcula-

tions can be used to evaluate boilers

that use steam deareation. When evalu-

ating a deareator, the cost of operation

should also be included. The operating

cost of the steam deareator can be esti-

mated by calculating the extra feed

water required to operate the deareator

and the energy loss associated with

venting the steam deareator.

In practice, 10 ppm of pure sodium

sulfite is needed to remove one ppm of

oxygen from water. One ppm of

sodium sulfite equates to 8.3 lbs per

million gallons of water. The amount

of dissolved oxygen in the water varies

with the water temperature. If 10 ppm

of oxygen is dissolved in the water,

83.0 lbs of sodium sulfite will be

Any chemical that is added

to the water can increase the frequency of

blow down, which affects operating costs of

the boiler. Fred Wiesler, Membrana

Liqui-Cel

® Membrane

Contactors degasify boiler feed

water, reduce chemical use and

blowdown frequency, resulting

in lower operating costs.

Table 1

Boiler Operating Details

Chemically Treated Feed Water Degassed Feed Water

Boiler capacity 10,000 lb/hr 10,000 lb/hr

Pressure 50 psig 50 psig

Efficiency 80% 80%

Fuel Natural Gas Natural Gas

Fuel cost 4.5 USD/ 1000 ft

3

4.5 USD/ 1000 ft

3

Fuel efficiency 1000 BTU/ft

3

1000 BTU/ft

3

Condensate return 30% 30%

Boiler blow down rate 10% 5%

Hours of operation 6600 hrs/yr (275 days/yr) 6600 hrs/yr (275 days/yr)

Feed water costs 1.2 USD/1000 gallons 1.2 USD/1000 gallons

Sodium Sulfite cost 0.5 USD/lb 0.5 USD/lb

Feed water temperature 60º F 60º F

Inlet Dissolved 9.0 ppm 0.5 ppm

Copyright 2004 by PennWell